BGA Inspection

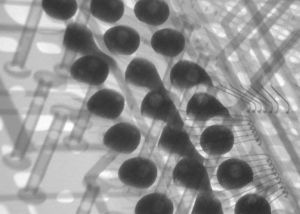

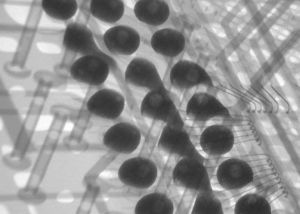

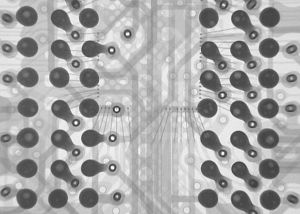

This is an angled view of BGA solder ball joints with voids. The tear dropped shape of the solder joint is caused by the reflowed solder wicking out from the pads to the trace on the PCB.

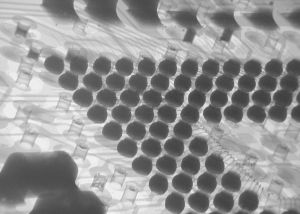

Off axis / compound angle capability with the Gen-X Series Systems can check for proper solder ball reflow by inspecting and measuring shape and size of the BGA ball joints.

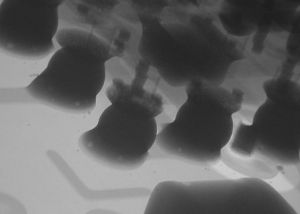

Sample x-ray image of non eutectic solder ball and its attachments to the bottom board pad and top component joint.

Example of oblique angle image of BGA solder ball joints showing inconsistent ball size and shape which is indicative of poor reflow. Void locations within the ball joints can also be seen.

858-385-1958

858-385-1958